True Colours of Innovation.

R&D I Product Testing I Analytical I Technical Support

Research & Development

Our approach to Product Development starts with understanding your operational needs and business objectives. We align your requirements with market trends, and create innovative coating solutions to support a sustainable future.

FCS Research and Development team continually explores new methods to exceed market needs, and set the standards in areas of innovation, application, performance and quality. FCS coating technologies meet the existing environmental legislations, and we are committed to bringing revolutionary ideas into life to minimise our environmental footprint.

We believe that innovation is the only formula for long term viability, we therefore invest in heavily in our Research and Development activities.

Product Testing and Analytical Services

Through our sophisticated physical and analytical testing laboratory, we ensure coatings performance at formulation, application and after-production stages.

Product Testing

Our coatings specialists are highly experienced in paint testing and analysis, and our impartial, un-biased testing methodology ensures that our products comply with the relevant OEM performance specifications, and environmental legislations. Our laboratory equipment is maintained and calibrated to the highest standards, and covers most of the requirements of the European Automotive specifications.

Our laboratory is ready to support our customers, so in addition to research and development related studies, we also conduct application related testing for customer support and process improvement purposes.

Physical Testing

Jet Wash, Car Wash

Multi Grit, Gravelometer

Abrex, Flat Bed Abrasion

Taber Abrasion, Auto Scratch

Hardness, Impact Indent

Chemical Testing

Cleaning Agents

Oils, Fuels

Acids, Alkalis

Weathering Tests

Humidity, Water Immersion

Xenon Weatherometer

QUV Weathering

Hygrothermal Ageing

Fogging/VOC Testing

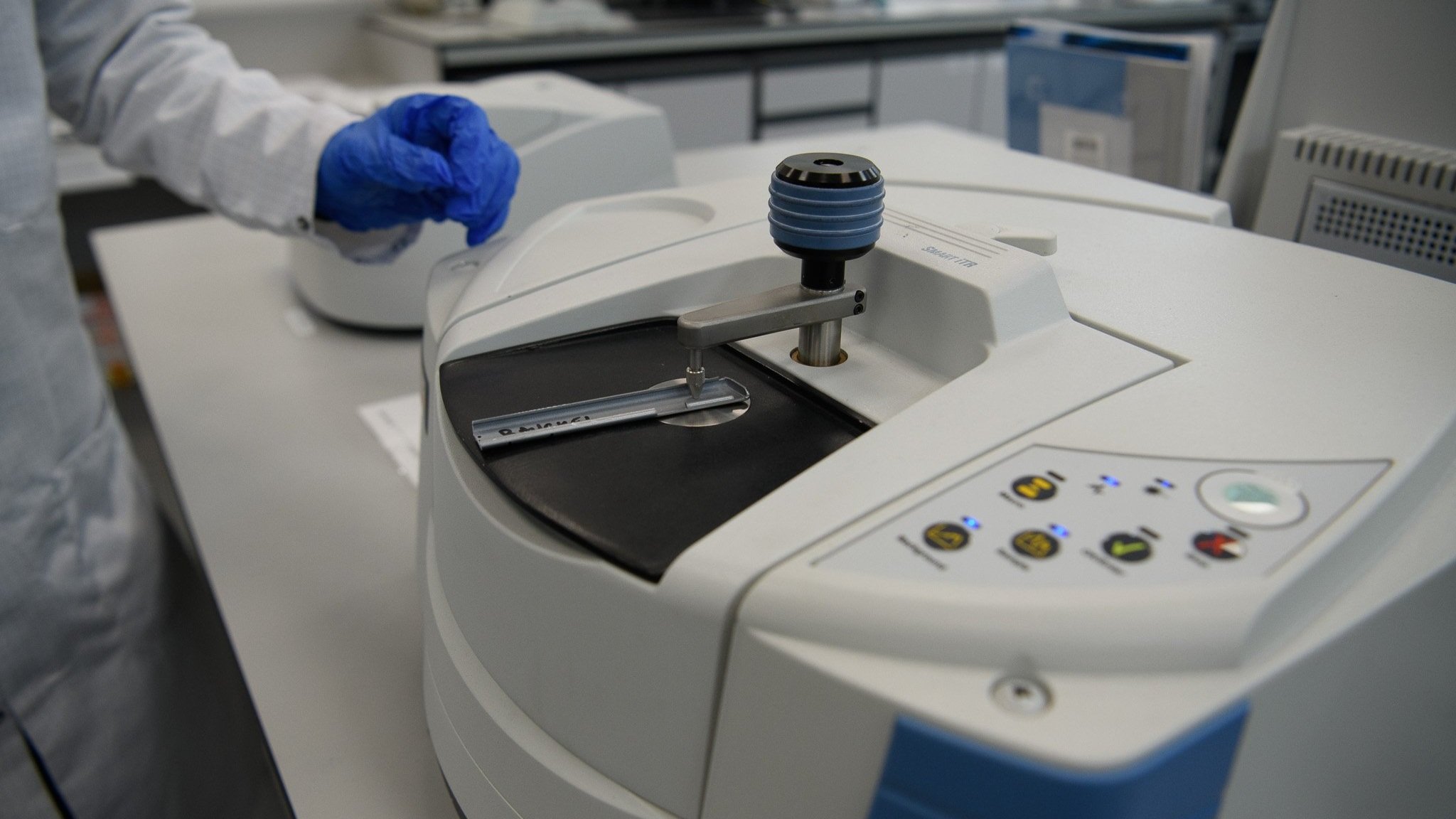

Analytical Laboratory

Our laboratory is equipped with advanced techniques capable of analysing all coating situations and problems. From film thickness, and paint structure analysis to advanced defect analysis, we are equipped to support our product and customers from new product concept through to series manufacture on painting lines.

We have helped our customers develop many applications by providing accurate and timely support from our experienced analytical team.

Examples are:

Root cause studies for improving production line performance,

Film thickness studies – supporting industrialisation and series production,

Curing rate studies - whether an application is fully cured or not,

Raw Material validation - ensuring the quality of our product,

Micro-analytical studies of defects.

GC-MS

FTIR

Optical Microscopy

Infrared Microscopy

UV-Vis

Centrifuge

Technical Support

With our dedicated technical service professionals, we offer total assurance on operational efficiency and customer satisfaction. From initial product enquiry to full volume production, we are here to support every aspect of your projects, ensuring maximum productivity and optimal use of resources.

Our experts have extensive product and process knowledge, and we can replicate many production and curing methods at the FCS Application Centre for trouble-free industrialisation and for process improvement purposes. Whether your business objective is improving your product or maximising your output, the FCS Technical Service Team will keep you moving towards your commercial and environmental goals.

20 Years - Average years of experience of our Technical Service Professionals.

Worldwide Support - We support projects wherever you are.

Diversity in Expertise - Our experts are knowledgeable in multiple coating technologies.